PYROBOOM – The New Standard For In-Situ Burning

In-situ burning, once reserved for oil spills in remote regions, is now considered a practical alternative to mechanical removal under specific conditions. Experience from the Deepwater Horizon Spill in the Gulf of Mexico validated “controlled burning” as an effective technique and PyroBoom® proved itself to be an excellent performer.

Performed properly, under the right conditions, In-situ burning can rapidly eliminate large quantities of oil, efficiently, with minimal and generally acceptable net environmental benefit. In the Gulf, PyroBoom® played a key role as In-situ burning helped to greatly reduce the amount of oil hitting the beaches and marshes.

In-situ burning is accepted for certain areas around the world, and is recognized by Environment Canada as a “viable alternative to mechanical methods.” For spills in Arctic waters, In-situ burning is often the only practical cleanup technique. Testing by the USCG and others has demonstrated Pyro- Boom’s ruggedness and effectiveness in ice infested waters.

Environment Canada’s Emergencies Science Division has also performed extensive testing of In-situ burning techniques and equipment and issued a report, In-situ Burning: A Cleanup Technique for Oil Spills on Water (2000).

THE SIMPLE SOLUTION, PYROBOOM

Developed specifically for In-situ burning of oil, PyroBoom® is the only product that meets all the responder’s needs from the Arctic to the tropics. In numerous burn tests, including those conducted in accordance with ASTM F2152, PyroBoom® has repeatedly demonstrated its effectiveness, survivability and ease of use.

ADVANTAGES OF PYROBOOM

Other fire booms, including those using active water-cooled fabric blankets, are subject to burnthrough and catastrophic failure, especially if any component in the complex water cooling system fails. In addition, these designs are complicated to use, requiring extensive training and practice. They become water-logged; the resulting dramatic weight gain makes subsequent retrieval difficult, and drying, storage and maintenance virtually impossible in field conditions. In contrast, the advantages of the PyroBoom® design and construction have been proven repeatedly over 25 years of development, testing and real-world use.

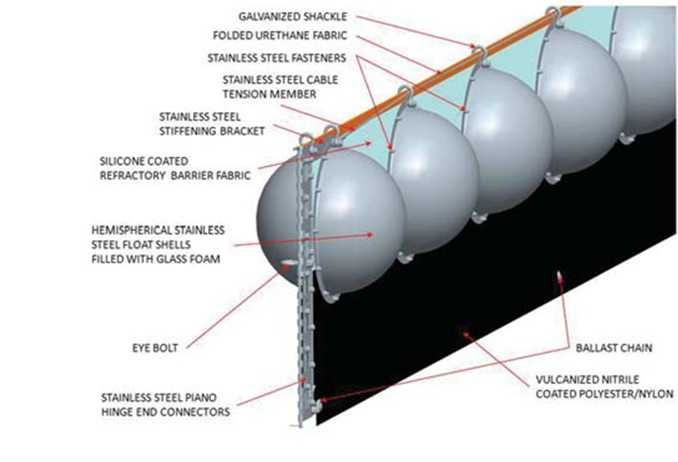

PATENTED REFRACTORY FABRIC

Our proprietary Inconel/Fiberfrax® refractory fabric with silicone coating has been proven in repeated burn tests at temperatures up to 1315°C/2400°F with no catastrophic failures.

FAIL-SAFE OPERATION

Degradation of the PyroBoom® refractory material is gradual, predictable and easily observed, ensuring fail-safe operation. Degraded refractory fabric is easy to replace in the field using only common hand tools.

STAINLESS/GLASS FOAM FLOATS

Stainless steel floats filled with glass foam have completed over 150 hours of burn testing with no damage.

SIMPLE MODULAR CONSTRUCTION

Boom components are assembled using stainless connectors and off-the-shelf fasteners, making it easy to extend, repair or replace boom sections in the field.

EASE OF USE

With no auxiliary pumps, compressors or delicate connections, using PyroBoom® is a simple four step process:

- Deploy

- Collect

- Burn

- Retrieve

Because PyroBoom® weighs practically the same wet or dry, retrieval is much easier than with watercooled booms.

LOW MAINTENANCE/LIFE-CYCLE COSTS

Except for replacing degraded refractory fabric after a burn campaign, PyroBoom® is virtually maintenance-free. It can be deployed, then retrieved and stored with no disassembly or extended drying period, making it ideal for training and drills.