Are You Safe?

Tampering of machinery space bilge water separators, oil content meters or the use of by-passes, so called magic pipes, is unfortunately still a very common occurrence on board vessels. The number of US prosecutions and heavy fines remain at a high level in spite of the enhanced environmental awareness. Whistle blowers are highly rewarded when reporting illegal discharges and the need to secure the evidence is vital. The US Department of justice target the oil record book when looking for inconsistencies as presenting wrong or falsified records will result in a fine regardless of where the actual discharge has taken place. If the crew has tried to hide evidence to the US Coast Guard or cover up records the prosecution will also include obstruction of justice that will add to the fines and possibly yield prison sentences.

Dilution of the oil content meter sample or simply closing the sample valve is by far the most common method to trick the oil content meter, but there are many ways. All modern oil content meters are logging the oil content, alarms and running status of the oily water separator with a time stamp. This is an IMO requirement from 2005 but surprisingly many engineers are unaware of this logging function. Mismatches between the log and the oil record book can be reason for prosecution. A record of straight 0 PPM (Parts Per Million) in the logger is a red flag that indicates that there has not been a sample flow through the oil content meter. A port state control officer can instruct the crew to operate the OWS and a history of straight 0 PPM will be hard to explain. Especially if the oil content meter does not show 0 PPM at the inspection where there must be a flow through the oil content meter. The IMO requirement of Oil content meter loggers does unfortunately not include the overboard valve position, the volume of discharged water or geographical position and the incomplete log is rather a danger to the crew than a way to prove compliance. So the need to have all operation data of the oily water separator securely logged is vital.

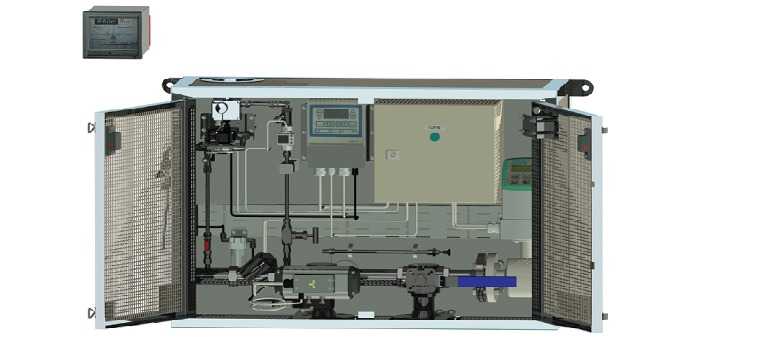

The Swedish Waste Water Treatment manufacturer Marinfloc developed the first Whitebox on the market in 1999 with over 900 units delivered since. The Whitebox is a control and monitoring system for bilge water discharge and is installed downstream of any Oily water separator. It contains all vital equipment concerning the discharge of treated bilge water such as an oil content meter, overboard three way valve, flow meter, sample water flow switch etc. all installed in a locked cage to which the Chief engineer has the key. Signals from the Whitebox of the oil content, valve positions, flow through the oil content meter, flow overboard, door position etc. together with the vessel GPS-position and time is recorded in a digital recorder installed in the engine control room. This enables the Chief engineer to have full control of the overboard discharge from the oily water separator as the Whitebox is tamper proof as long as it is locked. The main purpose of the Whitebox is to protect the crew and shipowner as it provides the evidence that the operations has been complaint and with no tampering of the equipment.

Marinfloc AB

Marinfloc AB delivers equipment for marine and offshore installations when it comes to Waste Water handling. Marinfloc deliver solutions for bilge and sewage treatment on-board vessels and bilge, sewage and deck drain treatment on-board offshore installations. Marinfloc AB is a company based in Sweden and was founded in 1996.

Marinfloc AB

www.marinfloc.com

Marinfloc@marinfloc.com